Zinc Flake Coatings

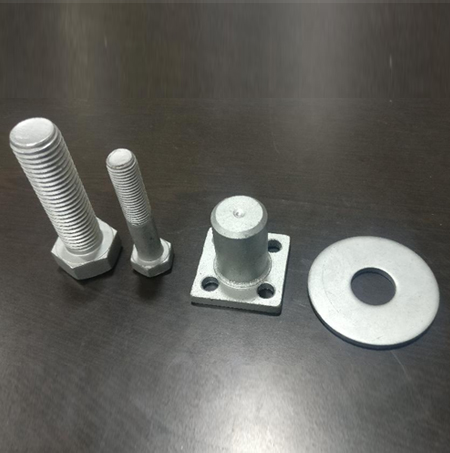

We are Manufacturer, Supplier, Exporter, Services Provider of Eco Friendly Zn Al (Zinc Aluminium) Flake Coatings, Corrosion Resistant, Abrasion Resistant, UV (Ultra Violet) Resistant, Chemical Resistant, Non Stick Surface Protection Coating for High Tensile Fasteners, Threaded Connecting Hardware Parts, Sintered parts, Bolts, Nuts, Rivers, Screws, Spring Steel Parts, Clips Clamps, Brackets, Stamping Parts, Brake Disc, Brake Drum, Brake Rotors and Our setup situated at Pune, Maharashtra, India.

Zinc - Aluminium Flake Coating Technology

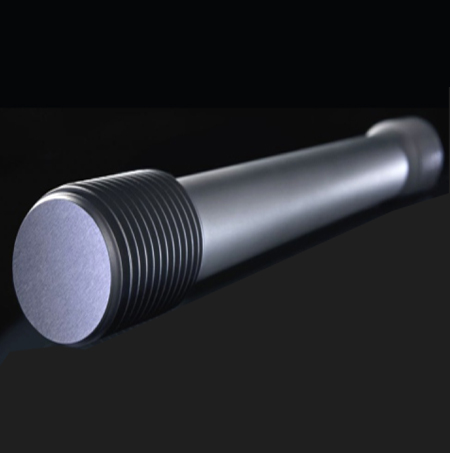

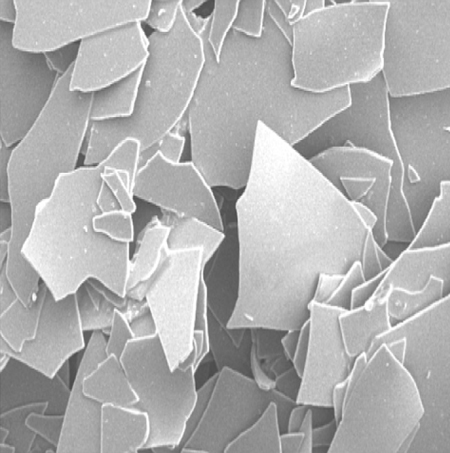

Zinc-Aluminium Flake Coating Technology, an innovative and eco-friendly solution, delivers superior corrosion protection for mass-produced hardware and metal parts in accordance with ISO 10683 standards. The coating consists of a base coat and top coat, ensuring robust micro-layer corrosion protection. With a remarkable SST resistance of 500-1000 hours, customizable based on customer requirements,The technology combines zinc and aluminum flakes with an electrically conductive binder system and integrated lubricants to control the coefficient of friction (COF) from 0.08 to 0.20.

Eco-friendly Zinc-Aluminium Flake Coating, a revolutionary solution, delivers superior Corrosion Resistance, Abrasion Resistance, UV Resistance, Chemical Resistance, and a Non-Stick Surface Protection Coating. Specifically designed for High Tensile Fasteners, Threaded Connecting Hardware Parts, Sintered parts, Bolts, Nuts, Rivers, Screws, Spring Steel Parts, Clips Clamps, Brackets, Stamping Parts, Brake Disc, Brake Drum, Brake Rotors.

Revitalize your products with our Zinc-Al Flake Coatings, offering an eco-conscious approach coupled with outstanding performance in diverse industrial applications.

Versatility is at the core of our coatings, designed for high-tensile fasteners, threaded connecting hardware, sintered parts, and a diverse range of components including bolts, nuts, rivers, screws, and automotive elements like brake discs and rotors. Beyond corrosion resistance, our eco-friendly coatings offer abrasion resistance, UV resistance, chemical resistance, and a non-stick surface protection coating. Embrace an eco-conscious approach without compromising performance. Our Zn Al Flake Coatings marry sustainability with outstanding protection, revitalizing your products in various industrial applications. Join us in setting new industry standards where performance meets responsibility, ensuring your assets are fortified for the long haul. Elevate your products with coatings that redefine possibilities in corrosion protection, setting the stage for a sustainable and durable future.

Zinc-Al Flake Coating Salient Features and Applications:

Superior Corrosion Protection: Offers high-performance corrosion protection for metal components, surpassing industry standards.Conductive Coating: Provides cathodic protection, preventing corrosion, and reduces white oxidation build-up.

Non-Electrolytic Application: Applied using mechanical techniques, avoiding the environmental impact associated with electroplating.

Dip-Spinning Process: Ideal for bulky metal components, forming a protective barrier against corrosive media.

Environmental Friendly: The coating process releases no hazardous gases, liquid, or solid waste, ensuring eco-friendliness.

Chrome-Free: Eliminates the use of harmful chrome, addressing environmental and health concerns.

Versatile Applications: Suitable for diverse environments, including Marine, Industrial, Humid, and Coastal settings.

High-Temperature Suitability: Withstands temperatures up to 350°C, making it suitable for various applications.

UV and Abrasion Resistance: Exhibits good resistance to UV rays and abrasion, ensuring durability in harsh conditions.

Zinc - Aluminium Flake Coating Properties:

SST Resistance: Customizable from 500 to 1500 hours, meeting specific customer requirements.Attractive Finishes: Offers bright silver and black finishes for enhanced aesthetics.

Hydrogen Embrittlement Freedom: Ensures freedom from hydrogen embrittlement issues.

Environmentally Friendly Process: No release of hazardous gases, liquid, or solid waste during the coating process.

Suitability for Torqueing: Ideal for applications requiring multiple torquing processes.

COF Control: Maintains COF between 0.08 to 0.20, ensuring optimal performance.

Regulatory Compliance: Meets standards such as ROHS, EVL, REACH, and WEEE.

Barrier and Cathodic Protection: Provides both barrier and cathodic protection for extended component life.

High-Temperature Application: Suitable for high-temperature applications up to 350°C.

UV and Abrasion Resistance: Offers good resistance to UV rays and abrasion, making it suitable for various environments.